-

Your cart is currently empty.

Proudly made in the USA

The leader in flyrod innovation

Proudly made in the USA

The leader in flyrod innovation

Over the decades, Snake Brand has been universally acknowledged as a beacon of creativity and innovation within the industry. Recognizing the detrimental impact of weight on the performance of even the most meticulously engineered fly rods, Snake Brand has consistently introduced groundbreaking advancements to the market, setting new benchmarks for excellence. Below is a timeline of our breakthrough concepts and notable contributions:

Introduced a standardized wire diameter for each guide size, tailored to its specific location on the fly rod, ensuring optimal performance and precision.

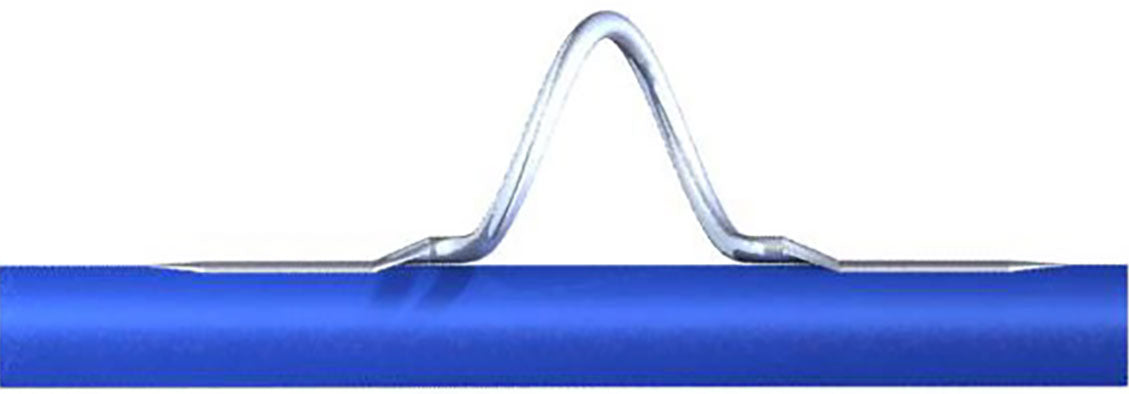

Implemented radiused tops on the guide feet, effectively minimizing the gap between the rod blank and the guide foot, enhancing the smoothness and integrity of the assembly.

Pioneered the use of tapered toes on the guide feet, crafted through precision dies. This innovation allows for a seamless transition for the thread, ensuring a smooth and secure wrap onto the guide foot.

Revolutionized guide feet stamping techniques to ensure equal length on both sides of the guide, promoting symmetry and balance in the assembly process.

Conducted a comprehensive analysis of existing guides for graphite and glass blanks, identifying significant deficiencies and opportunities for innovation. This led to the development of solutions that notably reduced labor costs in alignment and minimized weight, critical factors in enhancing performance.

Awarded Patent #6,851,216 for the Universal Guide, an industry milestone featuring concave radiused feet. This design introduced guides that are inherently self-orienting and self-aligning, streamlining the assembly process and improving rod performance.

Filed and were granted patents for Single Foot Guides and Tubeless Tip Top, further testament to our commitment to innovation and quality.

Launched a Light Series of guides specifically for the Scott Radian Project, showcasing our ability to tailor innovations to specific needs and projects.

Introduced a series of Spey Guides equipped with a heavier wire gauge (.038), engineered to enhance loading capabilities and durability, essential for handling trophy fish.

In our continuous quest for excellence and environmental integrity, we phased out Chromium from our manufacturing processes entirely by late 2021, achieving full compliance with RoHS and EPA standards. This decision underscores our unwavering dedication to not just environmental stewardship but also to providing products of unmatched quality.

Unveiled double and triple dyed burl woods for reel seat inserts, elevating the aesthetic appeal and functional sophistication of our products.

Introduced our latest innovation, the Single Foot Guide, marking yet another milestone in our journey of continuous improvement and leadership in the fly fishing industry.